Lucy gets first images of its first target asteroid, Dinkinesh

The asteroid probe Lucy has obtained its first images of Dinkinesh, the first of the ten asteroids the spacecraft is hoping to visit during its twelve year voyage to the Trojan asteroids.

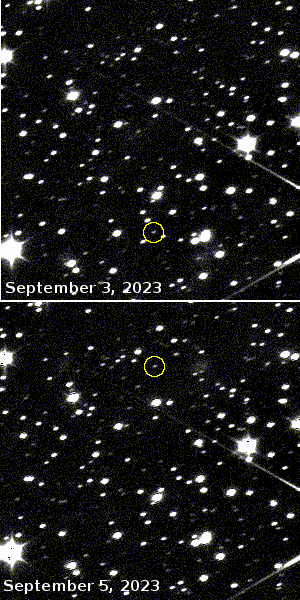

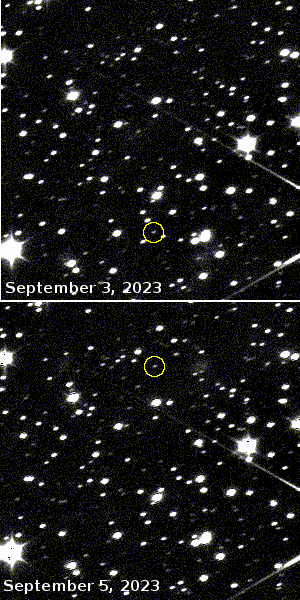

The image to the left shows the motion of that asteroid over a two day period when Lucy was getting the pictures.

Lucy took these images while it was 14 million miles (23 million km) away from the asteroid, which is only about a half-mile wide (1 km). Over the next two months, Lucy will continue toward Dinkinesh until its closest approach of 265 miles (425 km) on Nov. 1, 2023. The Lucy team will use this encounter as an opportunity to test out spacecraft systems and procedures, focusing on the spacecraft’s terminal tracking system, designed to keep the asteroid within the instruments’ fields of view as the spacecraft flies by at 10,000 mph (4.5 km/s). Lucy will continue to image the asteroid over the next months as part of its optical navigation program, which uses the asteroid’s apparent position against the star background to determine the relative position of Lucy and Dinkinesh to ensure an accurate flyby. Dinkinesh will remain an unresolved point of light during the long approach and won’t start to show surface detail until the day of the encounter.

Lucy’s primary targets are asteroids in the two Trojan groups that orbit the Sun in the two Lagrange points in same orbit as Jupiter, fore and aft of the gas giant by 60 degrees. For a map of Lucy’s full mission profile, go here.

The asteroid probe Lucy has obtained its first images of Dinkinesh, the first of the ten asteroids the spacecraft is hoping to visit during its twelve year voyage to the Trojan asteroids.

The image to the left shows the motion of that asteroid over a two day period when Lucy was getting the pictures.

Lucy took these images while it was 14 million miles (23 million km) away from the asteroid, which is only about a half-mile wide (1 km). Over the next two months, Lucy will continue toward Dinkinesh until its closest approach of 265 miles (425 km) on Nov. 1, 2023. The Lucy team will use this encounter as an opportunity to test out spacecraft systems and procedures, focusing on the spacecraft’s terminal tracking system, designed to keep the asteroid within the instruments’ fields of view as the spacecraft flies by at 10,000 mph (4.5 km/s). Lucy will continue to image the asteroid over the next months as part of its optical navigation program, which uses the asteroid’s apparent position against the star background to determine the relative position of Lucy and Dinkinesh to ensure an accurate flyby. Dinkinesh will remain an unresolved point of light during the long approach and won’t start to show surface detail until the day of the encounter.

Lucy’s primary targets are asteroids in the two Trojan groups that orbit the Sun in the two Lagrange points in same orbit as Jupiter, fore and aft of the gas giant by 60 degrees. For a map of Lucy’s full mission profile, go here.