Sierra Space successfully completes 2nd test-to-failure of a full scale LIFE inflatable module

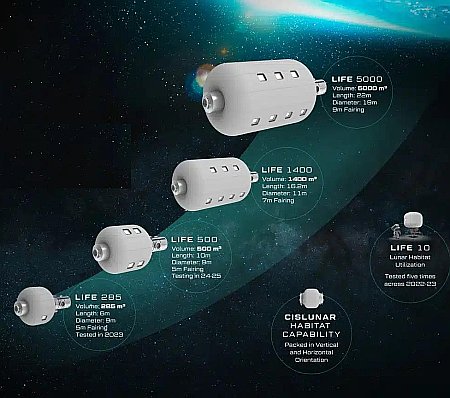

Sierra Space’s family of planned LIFE modules. Click for original

Sierra Space today announced it has completed a second successful test-to-failure of a full scale version of its LIFE inflatable module, intended for use not only on Blue Origin’s proposed Orbital Reef space station, but also available for purchase by other space station.

The latest test by the numbers:

- Company’s second Ultimate Burst Pressure test of a full-size, inflatable space station structure occurred on June 18

- Test unit stood over 20’ tall and was comparable in size to an average family home

- The article was 300 m³ in volume, or 1/3rd the volume of the International Space Station

- Test results exceeded NASA’s recommended x4 safety levels by 22%

- Two 4-ft x 4-ft steel blanking plates were integrated into the highest loaded cylinder section of the article; both were 50 lbs. lighter than the ones used in the first full-scale test and accommodate larger windows

The test article in the company’s historic first full-scale burst test last December peaked at 77 psi, which well exceeded (+27%) NASA’s recommended level of 60.8 psi (maximum operating pressure of 15.2 psi multiplied by a safety factor of four). This most recent test in June showed similar results – within five percent of the pressure loading of December’s test article – with this one reaching 74 psi, exceeding NASA’s 4x safety factor by 22 percent. These back-to-back test results accelerate Sierra Space’s path to flight certification, verifying scalability for 10 cubic-meter and up to 1,400 cubic-meter structures based on the company’s current softgoods inflatable architecture. Sierra Space is currently gearing up for a first test of its 500 cubic-meter space station technology next year.

Video of this test, dramatically edited with its own music soundtrack, can be seen at the link.

It is intriguing that the only developments related to Orbital Reef appear to come from Sierra Space. From Blue Origin — supposedly the lead company in that project — we hear almost nothing. Though Sierra Space has said the partnership is still solid, it has also made it clear it is building the LIFE module not just for Orbital Reef. I think it is hedging its bets, anticipating that Orbital Reef will be another Blue Origin dud, and wants to market itself to others.

Hat tip to stringer Jay for this story.

On Christmas Eve 1968 three Americans became the first humans to visit another world. What they did to celebrate was unexpected and profound, and will be remembered throughout all human history. Genesis: the Story of Apollo 8, Robert Zimmerman's classic history of humanity's first journey to another world, tells that story, and it is now available as both an ebook and an audiobook, both with a foreword by Valerie Anders and a new introduction by Robert Zimmerman.

The print edition can be purchased at Amazon or from any other book seller. If you want an autographed copy the price is $60 for the hardback and $45 for the paperback, plus $8 shipping for each. Go here for purchasing details. The ebook is available everywhere for $5.99 (before discount) at amazon, or direct from my ebook publisher, ebookit. If you buy it from ebookit you don't support the big tech companies and the author gets a bigger cut much sooner.

The audiobook is also available at all these vendors, and is also free with a 30-day trial membership to Audible.

"Not simply about one mission, [Genesis] is also the history of America's quest for the moon... Zimmerman has done a masterful job of tying disparate events together into a solid account of one of America's greatest human triumphs."--San Antonio Express-News

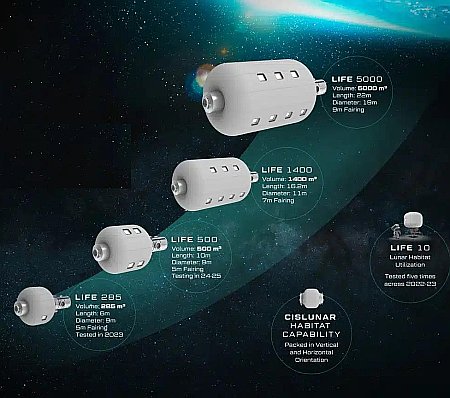

Sierra Space’s family of planned LIFE modules. Click for original

Sierra Space today announced it has completed a second successful test-to-failure of a full scale version of its LIFE inflatable module, intended for use not only on Blue Origin’s proposed Orbital Reef space station, but also available for purchase by other space station.

The latest test by the numbers:

- Company’s second Ultimate Burst Pressure test of a full-size, inflatable space station structure occurred on June 18

- Test unit stood over 20’ tall and was comparable in size to an average family home

- The article was 300 m³ in volume, or 1/3rd the volume of the International Space Station

- Test results exceeded NASA’s recommended x4 safety levels by 22%

- Two 4-ft x 4-ft steel blanking plates were integrated into the highest loaded cylinder section of the article; both were 50 lbs. lighter than the ones used in the first full-scale test and accommodate larger windows

The test article in the company’s historic first full-scale burst test last December peaked at 77 psi, which well exceeded (+27%) NASA’s recommended level of 60.8 psi (maximum operating pressure of 15.2 psi multiplied by a safety factor of four). This most recent test in June showed similar results – within five percent of the pressure loading of December’s test article – with this one reaching 74 psi, exceeding NASA’s 4x safety factor by 22 percent. These back-to-back test results accelerate Sierra Space’s path to flight certification, verifying scalability for 10 cubic-meter and up to 1,400 cubic-meter structures based on the company’s current softgoods inflatable architecture. Sierra Space is currently gearing up for a first test of its 500 cubic-meter space station technology next year.

Video of this test, dramatically edited with its own music soundtrack, can be seen at the link.

It is intriguing that the only developments related to Orbital Reef appear to come from Sierra Space. From Blue Origin — supposedly the lead company in that project — we hear almost nothing. Though Sierra Space has said the partnership is still solid, it has also made it clear it is building the LIFE module not just for Orbital Reef. I think it is hedging its bets, anticipating that Orbital Reef will be another Blue Origin dud, and wants to market itself to others.

Hat tip to stringer Jay for this story.

On Christmas Eve 1968 three Americans became the first humans to visit another world. What they did to celebrate was unexpected and profound, and will be remembered throughout all human history. Genesis: the Story of Apollo 8, Robert Zimmerman's classic history of humanity's first journey to another world, tells that story, and it is now available as both an ebook and an audiobook, both with a foreword by Valerie Anders and a new introduction by Robert Zimmerman.

The print edition can be purchased at Amazon or from any other book seller. If you want an autographed copy the price is $60 for the hardback and $45 for the paperback, plus $8 shipping for each. Go here for purchasing details. The ebook is available everywhere for $5.99 (before discount) at amazon, or direct from my ebook publisher, ebookit. If you buy it from ebookit you don't support the big tech companies and the author gets a bigger cut much sooner.

The audiobook is also available at all these vendors, and is also free with a 30-day trial membership to Audible.

"Not simply about one mission, [Genesis] is also the history of America's quest for the moon... Zimmerman has done a masterful job of tying disparate events together into a solid account of one of America's greatest human triumphs."--San Antonio Express-News

Re: Test-to-failure. I have tried to explain this to people. During some of the SpaceX development, they would fill fuel tanks until they failed. Sometimes, rather spectacularly. The Drive-By Media would only announce the failure, the ‘problem.’ SpaceX had found, determined the present (at the time) limits of the fuel tank. Every time SpaceX tested something, they learned more and more. The SuperHeavy booster is now operational as a one time use vehicle. It is well on the way to reusability.

Ronaldus Magnus wrote: “Re: Test-to-failure. I have tried to explain this to people.”

Test to failure can provide important information. When designing something, possible failures must be considered so that a failure can occur in a safe way. “Safe” in quotes, because a failure can be catastrophic. In the case of Orbital Reef, it would be nice if a bursting Life module didn’t throw shrapnel into the other modules. In an airliner, it would be best if failing fan, compressor, or turbine blades didn’t fly into the fuselage, so a containment ring is designed into the engine to try to stop a blade from going in that direction. In the case of a manned launch vehicle, it would be best if a propellant tank burst sideways and not forward into the manned spacecraft on top. You may remember that SLS was tested to failure, and it split a seam along the length of the tank, not forward toward the upper stage. It may seem counterintuitive to design-in a weak point, but it is merely that the rest of the design is stronger.

Sierra Space’s Life module is made in a new and largely untested method with materials used in new ways. Their two most recent tests have had panels built into the side of their module so that they can find how the construction behaves with windows put into the assembly. They are learning things that will enable them to build their modules in ways that are currently hypothetical.

Starship uses a new steel alloy. Their tests to failure gave them similar information on their new material and their welding methods as used in practical application. It is one thing to test a sample in the lab, but it is something more important to test the designed assembly.

I noticed that SpaceX didn’t announce in advance that a few tests were tests to failure, at least not in the early years. This may have been why so many in the media would announce the test as a failure. My experience is that it is important to announce in advance that a test would be to failure, otherwise bosses and customers get excited in a bad way.

Failures during development testing tell the engineers much about their design. They give knowledge about weaknesses and suggest ways to improve the design. Little was learned from the Apollo 4 test launch, which worked almost perfectly, but many lessons were learned from the Apollo 6 test launch, which was full of problems. The designers and the flight controllers learned more than they expected.

Qualification testing and acceptance testing should not have failures or other problems. By this time, the design must be well understood, otherwise you get problems like we saw with Starliner. Acceptance testing should find assembly problems, such as the one with the recent RUD of a Falcon upper stage engine. Why was the insufficiently tight clamp not found during the engine’s ground testing? Perhaps the vibrations on the test stand are different than those experienced during flight.