Because Boeing did nothing to replace a defective part, an airplane crashed killing fifteen

Despite previously identifying stress fractures in a part that held the engines to the wing on three different MD-11 airplanes, Boeing did nothing to replace the part, and so fifteen people died when the engine fell off a UPS cargo plane at take-off in November 2025.

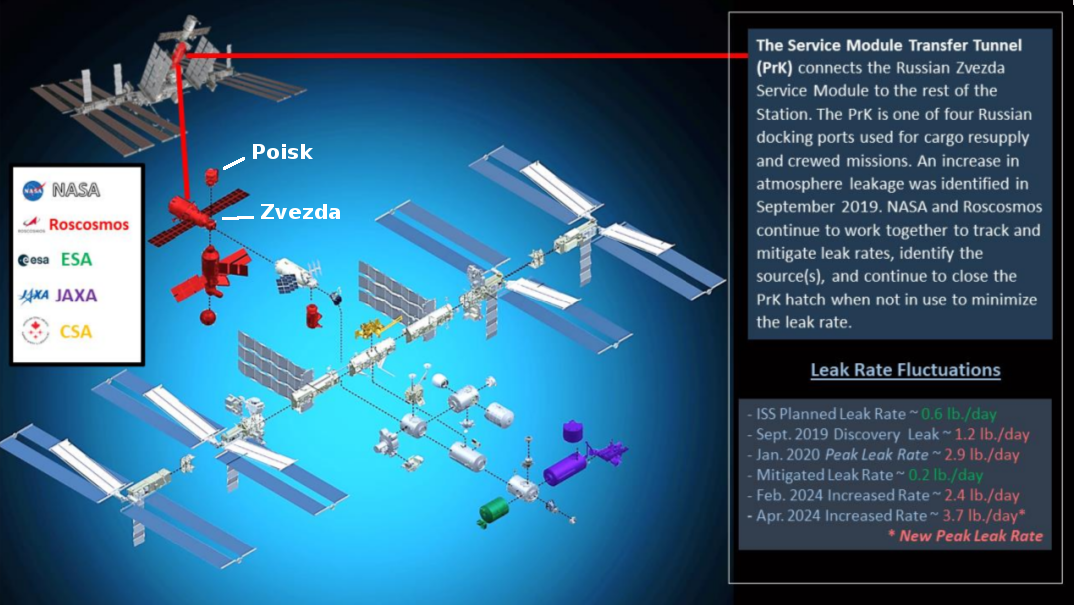

The sequence of images to the right, which I have annotated to show the engine breaking free from the wing, comes from the NTSB preliminary investigation report [pdf]. From the article at the link above:

In an update to its ongoing investigation into the crash of UPS Flight 2976, the National Transportation Safety Board [NTSB] said its team found fatigue cracking and overstress failure across much of the bearing race inside the area that attached the plane’s left engine to its wing. NTSB investigators then went back into Boeing service data and confirmed the design of the bearing assembly was consistent with the original design of that part.

[A] Boeing Service Letter dated Feb. 7, 2011 [and found by the NTSB], told operators the company was aware of four previous bearing race failures on three different airplanes. Boeing had seen the fractures of the bearing race, with the parts splitting in two and moving out of place. However, Boeing told operators its review of the bearing failure “would not result in a safety of flight condition.”

Boeing said further regular inspection of MD-11 airplanes would include a look at this bearing assembly, something scheduled for 60-month service intervals. And while Boeing used that service letter to discuss a new bearing assembly configuration, the installation of the original parts “was not prohibited.”

The plane itself had been built by McDonnell-Douglas, prior to its merger with Boeing. Nonetheless, Boeing engineers and managers were aware of this issue and did nothing to inform the owners of this plane so they could take action. In fact, Boeing apparently continued to ship out the original parts to airlines as replacement spares.

This is another example of a serious quality control problem at Boeing, where engineers no longer view serious engineering failures as serious engineering failures.

Despite previously identifying stress fractures in a part that held the engines to the wing on three different MD-11 airplanes, Boeing did nothing to replace the part, and so fifteen people died when the engine fell off a UPS cargo plane at take-off in November 2025.

The sequence of images to the right, which I have annotated to show the engine breaking free from the wing, comes from the NTSB preliminary investigation report [pdf]. From the article at the link above:

In an update to its ongoing investigation into the crash of UPS Flight 2976, the National Transportation Safety Board [NTSB] said its team found fatigue cracking and overstress failure across much of the bearing race inside the area that attached the plane’s left engine to its wing. NTSB investigators then went back into Boeing service data and confirmed the design of the bearing assembly was consistent with the original design of that part.

[A] Boeing Service Letter dated Feb. 7, 2011 [and found by the NTSB], told operators the company was aware of four previous bearing race failures on three different airplanes. Boeing had seen the fractures of the bearing race, with the parts splitting in two and moving out of place. However, Boeing told operators its review of the bearing failure “would not result in a safety of flight condition.”

Boeing said further regular inspection of MD-11 airplanes would include a look at this bearing assembly, something scheduled for 60-month service intervals. And while Boeing used that service letter to discuss a new bearing assembly configuration, the installation of the original parts “was not prohibited.”

The plane itself had been built by McDonnell-Douglas, prior to its merger with Boeing. Nonetheless, Boeing engineers and managers were aware of this issue and did nothing to inform the owners of this plane so they could take action. In fact, Boeing apparently continued to ship out the original parts to airlines as replacement spares.

This is another example of a serious quality control problem at Boeing, where engineers no longer view serious engineering failures as serious engineering failures.