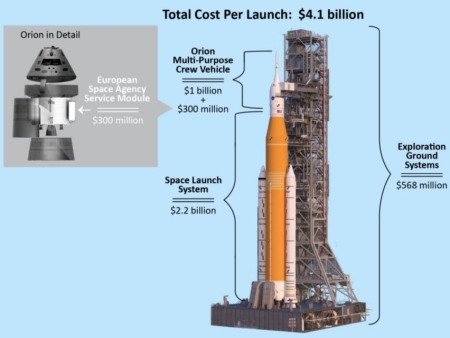

NASA testing SLS fuel leak repairs; UPDATE: Problems!

UPDATE: NASA posted a late update today describing vaguely the results of this fueling test, and revealed that while the test of the replacement seals appeared to go well, there were other problems:

During the test, teams encountered an issue with ground support equipment that reduced the flow of liquid hydrogen into the rocket. … Engineers will purge the line over the weekend to ensure proper environmental conditions and inspect the ground support equipment before replacing a filter suspected to be the cause of the reduced flow.

In other words, the SLS fueling system is like playing whack-a-mole. You fix one problem, and others show up.

I predicted this. It remains entirely possible NASA will not be able to complete a perfect full wet-dress rehearsal countdown in time to launch before April 6th, when this present launch window closes.

Original post:

———————-

NASA yesterday did an unannounced test fueling of its SLS rocket to check out the repairs in the fueling system.

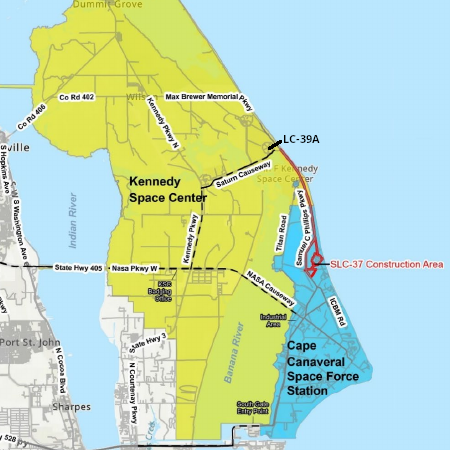

NASA is loading liquid hydrogen aboard its Space Launch System moon rocket at the Kennedy Space Center on Thursday for an unpublicized but crucial test of the repairs made to a leaky umbilical that derailed a countdown rehearsal on Feb. 2.

The operation to load liquid hydrogen into the huge fuel tank on the rocket’s core stage was thought to be already underway at launch complex 39B on Thursday morning. The test will determine if new seals installed in the launch pad umbilical are working. “As part of our work to assess the repair we made in the area where we saw elevated hydrogen gas concentrations during the previous wet dress rehearsal, engineers are testing the new seals by running some liquid hydrogen across the interface and partially filling the core stage liquid hydrogen tank. The data will inform the timeline for our next wet dress rehearsal,” a NASA spokesperson said about the previously unannounced test.

If the new seals work on these fueling tests, another full dress rehearsal countdown could take place as early as next week.

Posting is going to very light for the rest of the day. I am fighting a bad head cold and just want to go back to bed.

UPDATE: NASA posted a late update today describing vaguely the results of this fueling test, and revealed that while the test of the replacement seals appeared to go well, there were other problems:

During the test, teams encountered an issue with ground support equipment that reduced the flow of liquid hydrogen into the rocket. … Engineers will purge the line over the weekend to ensure proper environmental conditions and inspect the ground support equipment before replacing a filter suspected to be the cause of the reduced flow.

In other words, the SLS fueling system is like playing whack-a-mole. You fix one problem, and others show up.

I predicted this. It remains entirely possible NASA will not be able to complete a perfect full wet-dress rehearsal countdown in time to launch before April 6th, when this present launch window closes.

Original post:

———————-

NASA yesterday did an unannounced test fueling of its SLS rocket to check out the repairs in the fueling system.

NASA is loading liquid hydrogen aboard its Space Launch System moon rocket at the Kennedy Space Center on Thursday for an unpublicized but crucial test of the repairs made to a leaky umbilical that derailed a countdown rehearsal on Feb. 2.

The operation to load liquid hydrogen into the huge fuel tank on the rocket’s core stage was thought to be already underway at launch complex 39B on Thursday morning. The test will determine if new seals installed in the launch pad umbilical are working. “As part of our work to assess the repair we made in the area where we saw elevated hydrogen gas concentrations during the previous wet dress rehearsal, engineers are testing the new seals by running some liquid hydrogen across the interface and partially filling the core stage liquid hydrogen tank. The data will inform the timeline for our next wet dress rehearsal,” a NASA spokesperson said about the previously unannounced test.

If the new seals work on these fueling tests, another full dress rehearsal countdown could take place as early as next week.

Posting is going to very light for the rest of the day. I am fighting a bad head cold and just want to go back to bed.