NASA inspector general blasts Boeing’s management relating to its work on SLS’s new more powerful upper stage

Boeing’s schedule slips in building SLS’s upper stage

In a report issued today [pdf], NASA’s inspector general harshly criticized the Boeing managment and operations at its Michoud facility, where the company is developing SLS’s new more powerful upper stage. From the report’s executive summary:

Quality control issues at Michoud are largely due to the lack of a sufficient number of rained and experienced aerospace workers at Boeing. To mitigate these challenges, Boeing provides training and work orders to its employees. Considering the significant quality control deficiencies at Michoud, we found these efforts to be inadequate. For example, during our visit to Michoud in April 2023, we observed a liquid oxygen fuel tank dome—a critical component of the SLS Core Stage 3—segregated and pending disposition on whether and how it can safely be used going forward due to welds that did not meet NASA specifications. According to NASA officials, the welding issues arose due to Boeing’s inexperienced technicians and inadequate work order planning and supervision. The lack of a trained and qualified workforce increases the risk that Boeing will continue to manufacture parts and components that do not adhere to NASA requirements and industry standards.

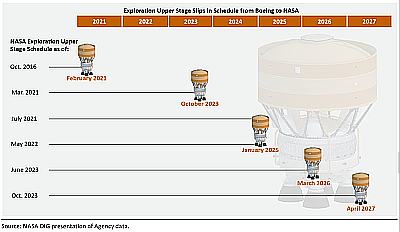

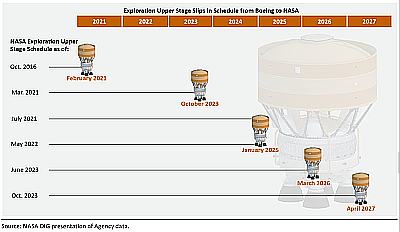

The report also notes that delivery of that upper stage has been delayed from 2021 to 2027 (as shown by the graph to the right, taken from the IG report), and its cost has risen from $962 million to almost $2.8 billion. It also notes quite bluntly that:

Boeing’s quality management system at Michoud does not effectively adhere to industry standards or NASA requirements, resulting in production delays to the SLS core and upper stages and increased risk to the integrated spacecraft. … Boeing’s process for addressing contractual noncompliance has been ineffective, and the company has generally been nonresponsive in taking corrective actions when the same quality control issues reoccur.

Sound familiar? It should. These issues appear to be the same kind of quality control problems that have plagued Starliner, and are also the same kind of problems that had NASA reject Boeing’s bid to provide cargo to its Lunar Gateway station, and state while doing so that it will no longer consider future Boeing bids until the company straightens itself out.

It appears from today’s inspector general report that Boeing has fixed nothing. The report recommends some additional supervision of Boeing from NASA, and more importantly suggests the agency “institute financial penalties for Boeing’s noncompliance with quality control standards.”

On Christmas Eve 1968 three Americans became the first humans to visit another world. What they did to celebrate was unexpected and profound, and will be remembered throughout all human history. Genesis: the Story of Apollo 8, Robert Zimmerman's classic history of humanity's first journey to another world, tells that story, and it is now available as both an ebook and an audiobook, both with a foreword by Valerie Anders and a new introduction by Robert Zimmerman.

The print edition can be purchased at Amazon or from any other book seller. If you want an autographed copy the price is $60 for the hardback and $45 for the paperback, plus $8 shipping for each. Go here for purchasing details. The ebook is available everywhere for $5.99 (before discount) at amazon, or direct from my ebook publisher, ebookit. If you buy it from ebookit you don't support the big tech companies and the author gets a bigger cut much sooner.

The audiobook is also available at all these vendors, and is also free with a 30-day trial membership to Audible.

"Not simply about one mission, [Genesis] is also the history of America's quest for the moon... Zimmerman has done a masterful job of tying disparate events together into a solid account of one of America's greatest human triumphs."--San Antonio Express-News

Boeing’s schedule slips in building SLS’s upper stage

In a report issued today [pdf], NASA’s inspector general harshly criticized the Boeing managment and operations at its Michoud facility, where the company is developing SLS’s new more powerful upper stage. From the report’s executive summary:

Quality control issues at Michoud are largely due to the lack of a sufficient number of rained and experienced aerospace workers at Boeing. To mitigate these challenges, Boeing provides training and work orders to its employees. Considering the significant quality control deficiencies at Michoud, we found these efforts to be inadequate. For example, during our visit to Michoud in April 2023, we observed a liquid oxygen fuel tank dome—a critical component of the SLS Core Stage 3—segregated and pending disposition on whether and how it can safely be used going forward due to welds that did not meet NASA specifications. According to NASA officials, the welding issues arose due to Boeing’s inexperienced technicians and inadequate work order planning and supervision. The lack of a trained and qualified workforce increases the risk that Boeing will continue to manufacture parts and components that do not adhere to NASA requirements and industry standards.

The report also notes that delivery of that upper stage has been delayed from 2021 to 2027 (as shown by the graph to the right, taken from the IG report), and its cost has risen from $962 million to almost $2.8 billion. It also notes quite bluntly that:

Boeing’s quality management system at Michoud does not effectively adhere to industry standards or NASA requirements, resulting in production delays to the SLS core and upper stages and increased risk to the integrated spacecraft. … Boeing’s process for addressing contractual noncompliance has been ineffective, and the company has generally been nonresponsive in taking corrective actions when the same quality control issues reoccur.

Sound familiar? It should. These issues appear to be the same kind of quality control problems that have plagued Starliner, and are also the same kind of problems that had NASA reject Boeing’s bid to provide cargo to its Lunar Gateway station, and state while doing so that it will no longer consider future Boeing bids until the company straightens itself out.

It appears from today’s inspector general report that Boeing has fixed nothing. The report recommends some additional supervision of Boeing from NASA, and more importantly suggests the agency “institute financial penalties for Boeing’s noncompliance with quality control standards.”

On Christmas Eve 1968 three Americans became the first humans to visit another world. What they did to celebrate was unexpected and profound, and will be remembered throughout all human history. Genesis: the Story of Apollo 8, Robert Zimmerman's classic history of humanity's first journey to another world, tells that story, and it is now available as both an ebook and an audiobook, both with a foreword by Valerie Anders and a new introduction by Robert Zimmerman.

The print edition can be purchased at Amazon or from any other book seller. If you want an autographed copy the price is $60 for the hardback and $45 for the paperback, plus $8 shipping for each. Go here for purchasing details. The ebook is available everywhere for $5.99 (before discount) at amazon, or direct from my ebook publisher, ebookit. If you buy it from ebookit you don't support the big tech companies and the author gets a bigger cut much sooner.

The audiobook is also available at all these vendors, and is also free with a 30-day trial membership to Audible.

"Not simply about one mission, [Genesis] is also the history of America's quest for the moon... Zimmerman has done a masterful job of tying disparate events together into a solid account of one of America's greatest human triumphs."--San Antonio Express-News

If you’re cutting and pasting from the executive summary, the IG needs some QA as well. rained = trained. Boeing’sinexperienced .

I’m beginning to wonder if it’s not just a Boeing management problem. Lack of a trained and skilled workforce seems to be a recurring theme all around US industry. Maybe the country can’t produce trainable workforce anymore, or skilled tradesmen like welders.

John: The missing space was likely my mistake in cutting and pasting from the pdf.

Nonetheless, you ask a good question, one that I have been asking myself in a number of essays in the past few years. See for example this Feburary essay: Have modern space engineers forgotten the importance of keeping things simple?

“I’m beginning to wonder if it’s not just a Boeing management problem.”

You can quit wondering – it probably is. A friend told me that years ago another large aerospace company had developed a test to measure management potential in senior blue collar workers. They measured basic knowledge in finance, science, logical thinking, etc.

As a final test he says they administered the test to a group of workers, and to a control group of senior managers that they hoped to impress.

There was a decent rate of potential shown in the workers, but a majority of the senior managers whiffed! The program was shelved.

“lack of a sufficient number of trained and experienced aerospace workers at Boeing”

No hablo inglés! No hablo inglés!

https://t.ly/P2y6Z

Sucks when an engineering company is run by accountants and CYA experts. SLS should be given the Ol’ Yeller treatment, anyway, especially if it can’t be transferred to a competently-run engineering firm. Right now, NASA (and the taxpayer) are just subsidizing failure at a grand scale.

The SLS core worked fine–the X-37 is a good Boeing product.

I sense something else going on–I just can’t prove it.

I’m guessing the NASA astronaut corps – especially those who might be in line for selection to the Artemis 4 mission – will have some misgivings about flying atop this thing on what is, thus far, scheduled to be its very first launch.

“I’m guessing the NASA astronaut corps – especially those who might be in line for selection to the Artemis 4 mission – will have some misgivings about flying atop this thing on what is, thus far, scheduled to be its very first launch.”

Seriously, this actually *should* be raising questions about the flight safety of the Block 1B SLS. Is anyone at NASA actually looking at that now? The OIG says that Boeing unqualified welders doing shoddy work to the tune of 70+ corrective actions caught by Defense Contracts Management Agency, which is only looking at contract violations. What build errors outside contract violations have and have not been caught by Boeing and NASA?

After all, it’s not like SLS had a great LOC risk assessment to begin with.

Industry executives have and still are falling into the fallacy that any employee without a collage degree is replaceable with any other employee.

They are now expanding this experiment (the theory from collage professors) into the area of trained and skilled workers.

In highly specialized fields like aerospace experience counts. You lose a HUGE amount of (as they call it) tribal knowledge by switching people around. It takes years to master a skill and mastery is what is needed.

Tribal knowledge is a national asset.

Bean counters–whether they be Boeing shareholders or libertarian zealots who want to kill national programs–have done enough damage.

It isn’t just DEI that has hurt aerospace…though that is part of it.

Boeing needs to finish things.

We called it “domain knowledge”. Management believed any engineer could be replaced with a generic contract engineer. No need to know how the widget you were manufacturing worked or its important specifications. No need to know how the machine that made the widget performed in concert with the widget design to produce a lowest cost, best performing widget.

“… Michoud officials stated that it has been difficult to attract and retain a contractor workforce with aerospace manufacturing experience in part due to Michoud’s geographical location in New Orleans, Louisiana, and lower employee compensation relative to other aerospace competitors. …”

allow me to speculate …. Boeing is using a contractor workforce because otherwise the employee alternative would saddle the company with union work rules and high severance payments when the rocket program winds down. And the New Orleans location was chosen to satisfy Congressional demands that the work be performed in specific districts.

Here is a quote from a critic of SLS, mind you:

“It could be that because Boeing took over the U.S. Government-owned Michoud facility outside of New Orleans well after the Lockheed Martin shut down the Shuttle External Tank (ET) production, that the general area lost a significant number of workers that had the skills needed for the SLS production.”

https://forum.nasaspaceflight.com/index.php?topic=61329.msg2614585#msg2614585

That’s what happens when you lay folks off en masse–whether it is a Proxmire or a Stonecipher that does it.

Rocket tech is a national asset for its own sake..

If “Coastal Ron” as he calls himself is accurate–it shows how a government run facility that values tribal knowledge is better than a private outfit–especially if it is Boeing.

This right here is why I think MSFC and proper funding of it is a national security asset.

SLS as is outperforms Starship as is for the moment.

When I started working in that aerospace company we had a dedicated engineer for each specialty. Electrical, mechanical, chemical and so on. Even our CEO was an electrical engineer.

Each had at least 20 years experience in the industry.

By the time I left that had dropped to less than 5 years of experience.

Our new mechanical engineer fresh out of collage had never even seen a machine shop let alone had experience working with any or our CNC machines. I had to teach this kid how to run a drill press.

Engineering schools used to make sure the students had some experience before they left school. Knew how to use the tools of their field.

That company now has a policy of rotating all of its senor staff and engineer’s between the different departments. So that if someone “quits” their job can be covered quickly. They are trying to extend this down to all the other employees. They are now rotating them every year or two.

Quality has dropped very fast. After 4 years they are starting to realize its not working very well.

That’s got to stop…I don’t know what it will take to get good people back…If I were Bezos, I would hire retirees just to have them mentor others.

That’s how I look at what NASA centers should be.

Asset preservation has to mean more than money.