April 29, 2024 Quick space links

Courtesy of BtB’s stringer Jay, who has returned from a weeklong work trip in “the People’s Republic of California.” This post is also an open thread. I welcome my readers to post any comments or additional links relating to any space issues, even if unrelated to the links below.

- SES’s O3b mPOWER satellite constellation starts providing service

That makes at least three constellations (including Starlink and OneWeb) in orbit ahead of and operational before Amazon has launched a single satelltie in its Kuiper constellation

- Hyimpulse’s suborbital test launch from Southern Launch in Australia is now targeting May 2, 2024

Though I saw no announcement, they apparently got their launch licence from the Australian government.

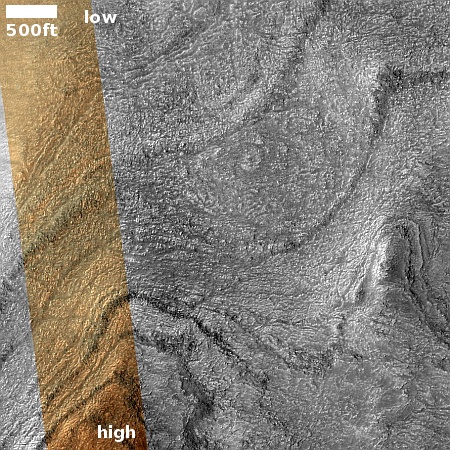

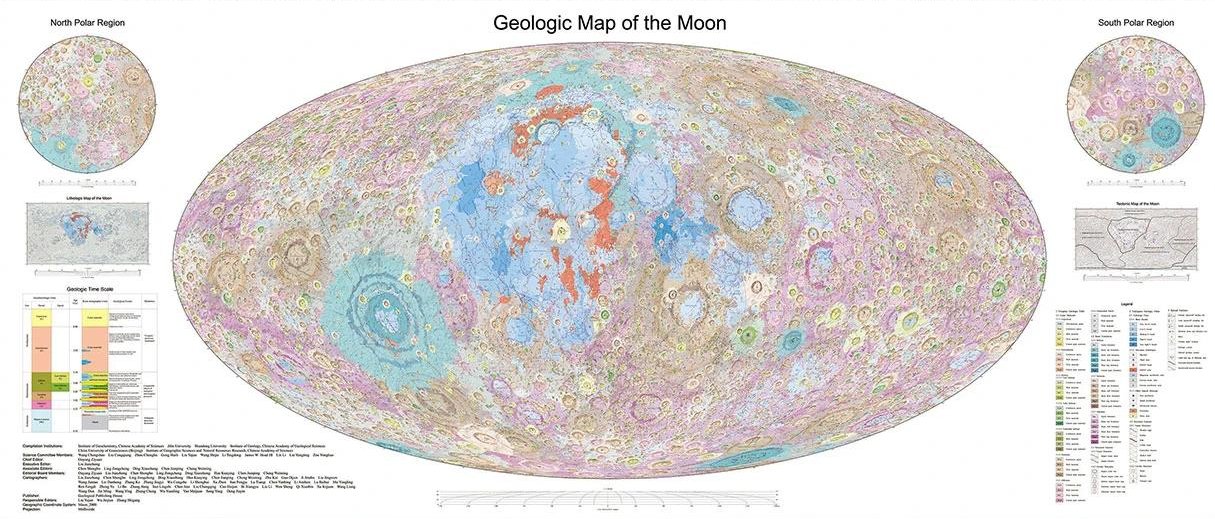

- Long March 5 ready to launch China’s Chang’e-6 sample return mission to the Moon’s far side

According to the article, the core stage will not reach orbit and thus not make an uncontrolled re-entry, as the core stage of the more powerful Long March 5B varient does.

- Chinese reporter notes the increase in hotel prices near the Wenchang spaceport when a manned launch is scheduled

The communists might claim they think capitalism is bad and they are building a Marxist utopia, but the invisible hand of capitalism always rules.

Courtesy of BtB’s stringer Jay, who has returned from a weeklong work trip in “the People’s Republic of California.” This post is also an open thread. I welcome my readers to post any comments or additional links relating to any space issues, even if unrelated to the links below.

- SES’s O3b mPOWER satellite constellation starts providing service

That makes at least three constellations (including Starlink and OneWeb) in orbit ahead of and operational before Amazon has launched a single satelltie in its Kuiper constellation

- Hyimpulse’s suborbital test launch from Southern Launch in Australia is now targeting May 2, 2024

Though I saw no announcement, they apparently got their launch licence from the Australian government.

- Long March 5 ready to launch China’s Chang’e-6 sample return mission to the Moon’s far side

According to the article, the core stage will not reach orbit and thus not make an uncontrolled re-entry, as the core stage of the more powerful Long March 5B varient does.

- Chinese reporter notes the increase in hotel prices near the Wenchang spaceport when a manned launch is scheduled

The communists might claim they think capitalism is bad and they are building a Marxist utopia, but the invisible hand of capitalism always rules.