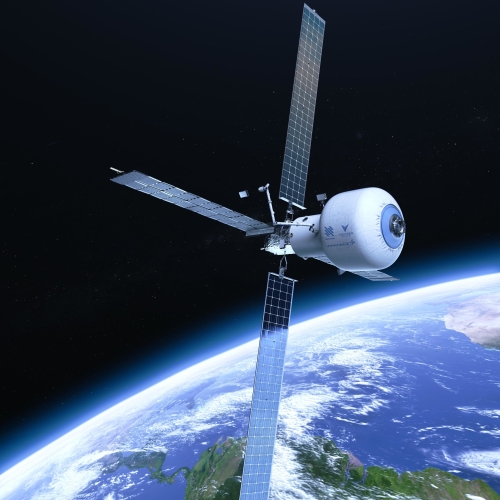

Voyager Space partners with Airbus to build its Starlab space station

Voyager Space, one of the three companies with a contract from NASA to develop a commercial private space station, has now signed a partnership agreement with the European aerospace company Airbus to work together to build its Starlab space station.

The companies announced Aug. 2 the creation of a joint venture, also called Starlab, that will be responsible for the development and operation of the station. The joint venture builds upon an agreement announced in January where Voyager selected Airbus to provide technical support for the proposed station.

“This transatlantic venture with footprints on both sides of the ocean aligns the interests of both ourselves and Voyager and our respective space agencies,” said Jean-Marc Nasr, head of space systems at Airbus, in a statement. “Together our teams are focused on creating an unmatched space destination both technologically and as a business operation.”

Though no specifics of the deal were released, Voyager will continue to retain 51% control. It appears that Voyager’s goal with this deal is to get its foot in the door of Europe. With ESA no longer considering doing any work on the space stations of either China or Russia, it needs a place to go after ISS is retired. By signing up Airbus as a partner Voyager makes Starlab the most likely go-to station for these European companies and governments.

Isn’t private enterprise and freedom wonderful? Without even trying Europe is going to get a space station of its own, and it will do it by hiring this private consortium of American and European companies.

Hat tip to Jay, BtB’s stringer.

Voyager Space, one of the three companies with a contract from NASA to develop a commercial private space station, has now signed a partnership agreement with the European aerospace company Airbus to work together to build its Starlab space station.

The companies announced Aug. 2 the creation of a joint venture, also called Starlab, that will be responsible for the development and operation of the station. The joint venture builds upon an agreement announced in January where Voyager selected Airbus to provide technical support for the proposed station.

“This transatlantic venture with footprints on both sides of the ocean aligns the interests of both ourselves and Voyager and our respective space agencies,” said Jean-Marc Nasr, head of space systems at Airbus, in a statement. “Together our teams are focused on creating an unmatched space destination both technologically and as a business operation.”

Though no specifics of the deal were released, Voyager will continue to retain 51% control. It appears that Voyager’s goal with this deal is to get its foot in the door of Europe. With ESA no longer considering doing any work on the space stations of either China or Russia, it needs a place to go after ISS is retired. By signing up Airbus as a partner Voyager makes Starlab the most likely go-to station for these European companies and governments.

Isn’t private enterprise and freedom wonderful? Without even trying Europe is going to get a space station of its own, and it will do it by hiring this private consortium of American and European companies.

Hat tip to Jay, BtB’s stringer.