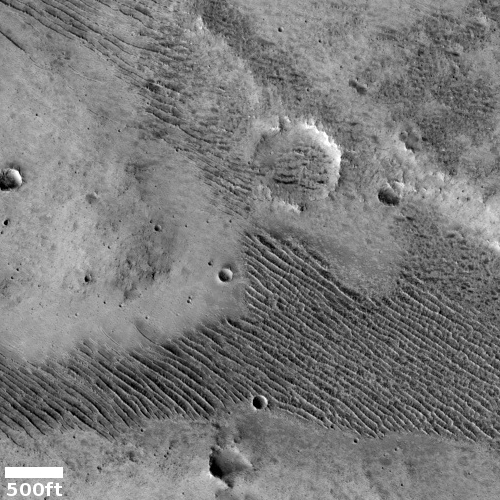

Curiosity faces the mountains

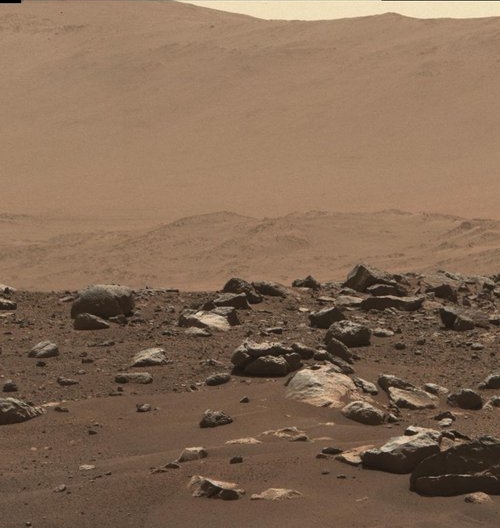

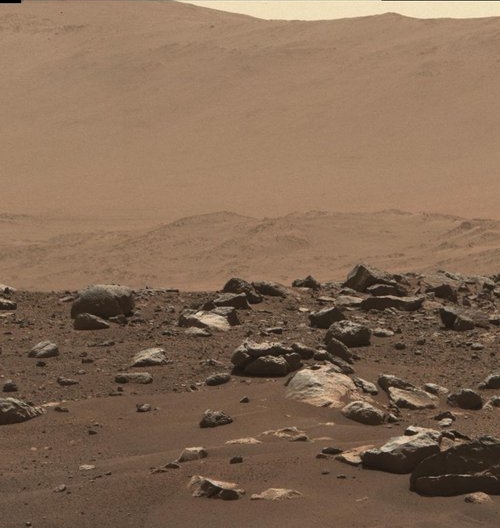

A cropped section from Perserverance’s 1st panorama.

Click for full image.

Though the present excitement over the spectacular images and sounds coming down from Perseverance is certainly warranted, what must be understood is that this rover is presently only at the beginning of its journey, and is thus sitting on relatively boring terrain, from a merely visual perspective. The scientists might be excited, but to the general public, all we really are seeing is a flat dusty desert with some scattered rocks on the floor. In the far distance can be seen some hills and mountains (Jezero Crater’s rim), but they are very far away.

Curiosity, which the press and the public has largely forgotten about, is actually just beginning what will likely be the most breath-taking part of its journey. As I noted in my last rover update last week, Curiosity is now at the very base of Mount Sharp, and is about to enter the mountain’s canyons and initial slopes. For its past eight-plus years of roving it has been on the flat floor of Gale Crater, followed by some weaving among the smallest foothills of Mount Sharp. The views have been intriguing and exciting from a research perspective, but hardly breath-taking from a picture-taking point of view.

That is now changing. The picture below, taken by Curiosity just this week, gives us a taste of what is to come.

» Read more

A cropped section from Perserverance’s 1st panorama.

Click for full image.

Though the present excitement over the spectacular images and sounds coming down from Perseverance is certainly warranted, what must be understood is that this rover is presently only at the beginning of its journey, and is thus sitting on relatively boring terrain, from a merely visual perspective. The scientists might be excited, but to the general public, all we really are seeing is a flat dusty desert with some scattered rocks on the floor. In the far distance can be seen some hills and mountains (Jezero Crater’s rim), but they are very far away.

Curiosity, which the press and the public has largely forgotten about, is actually just beginning what will likely be the most breath-taking part of its journey. As I noted in my last rover update last week, Curiosity is now at the very base of Mount Sharp, and is about to enter the mountain’s canyons and initial slopes. For its past eight-plus years of roving it has been on the flat floor of Gale Crater, followed by some weaving among the smallest foothills of Mount Sharp. The views have been intriguing and exciting from a research perspective, but hardly breath-taking from a picture-taking point of view.

That is now changing. The picture below, taken by Curiosity just this week, gives us a taste of what is to come.

» Read more